Table Of Content

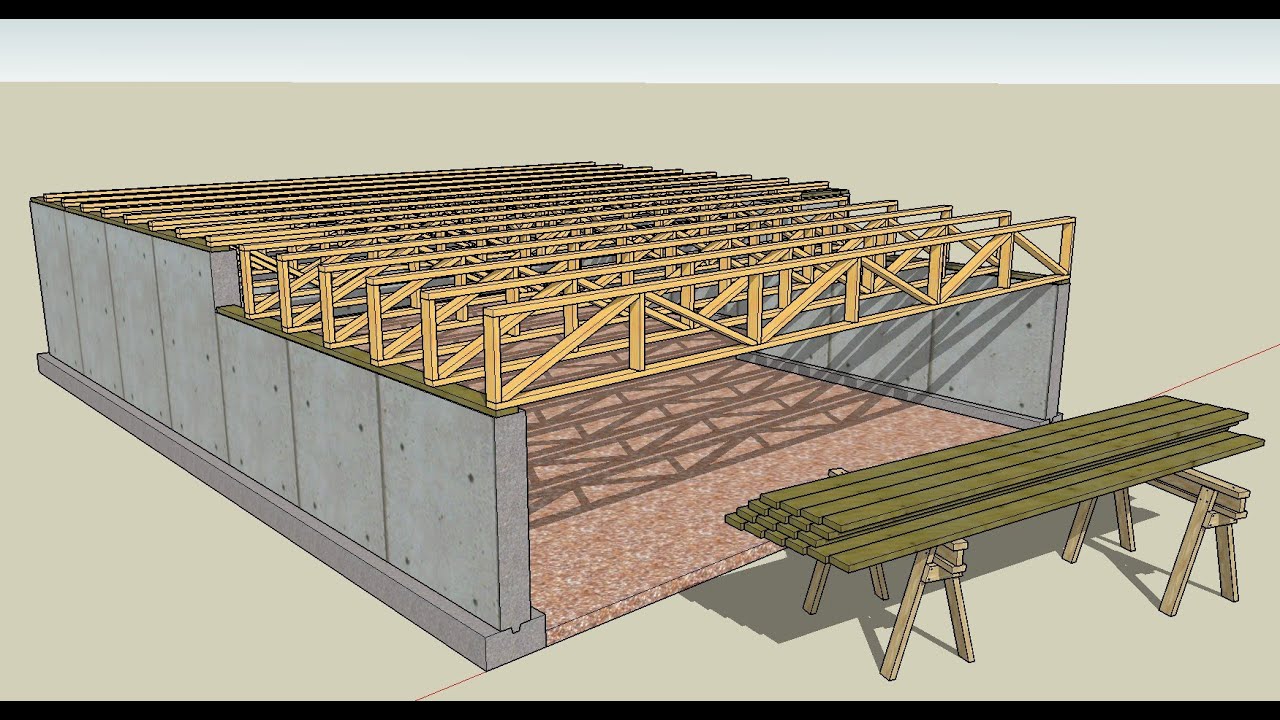

Based on the design and configuration, Pratt and Warren are two basic types of floor trusses. Open webbing provides great benefits to plumbers and electricians, without the need to spend time cutting holes in floor members. Less cutting reduces jobsite labor and reduces potentially critical errors that could result in compromising the structural integrity of the components.

Different Types of Floor Truss

For floor trusses, the top chord material is usually cut from 2x3 or 2x4 material, but instances utilizing 2x6 top chord material for floor trusses can also be found. Typically in floor trusses, the material is oriented in a flat or 4x2 position. The top chord is intersected by the bottom chord and web members at various points through the truss creating a joint that is secured by metal connector plates. A top chord can be multiple pieces of lumber secured by a metal plate known as a splice, either at a joint or mid panel. While a vast majority of trusses will have top chords of the same species and grade, changes in both lumber species and grade are possible at splice points. Often web members in compression require continuous lateral restraints (CLR) to prevent buckling under the applied design loads.

Floor Trusses

Structural support, usually a beam, wall, or post that is designed by the building designer to carry the truss reaction loads to the foundation. When it’s to the floor joist, they use solid dimensional lumber that is limited in span based on the wood species, its grade, depth, and other factors. In the past, they were a must for construction work, but these days more people go for engineered wood products. These joists are not the best for the environment because companies must cut many trees to make the joists. TrimJoist® floor truss products are used by discerning builders, contractors, and remodelers and specified by leading architects, engineers, and designers.

Floor strength for a second story basketball court

Likewise, bearings can be beams, ledgers, headers, or posts made from any of the above-mentioned materials. Regardless, the bearing must be strong enough to support the loads transferred from the trusses above. If the bearing material is not strong enough, crushing can occur when the truss is under designed loads. This results in serviceability issues like cracked sheetrock and dips in ceilings above and floors below.

Additional Resources

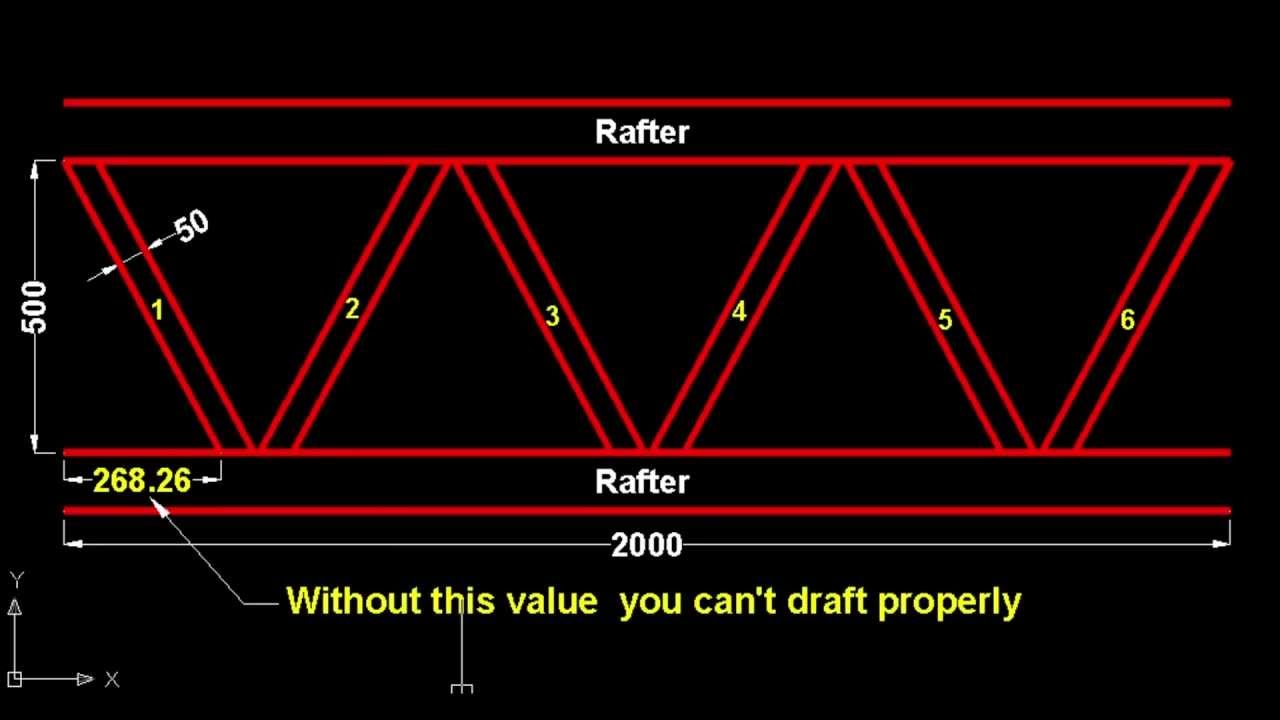

It is the horizontal distance between two exterior bearings and is typically the width of the structure. Special attention should be taken not to confuse any cantilever portion of the truss with its span. For example, if the walls of the structure are spaced 24’ apart and the truss has a 4’ cantilever on one side, the overall truss length would be 28’ with a span of 24’ and a 4’ cantilever. Truss span can vary widely from as small as 1’ (or smaller if necessary) to over 100’ in length.

ELIMINATE WASTE AND IMPROVE CYCLE TIME WITH OPEN WEB FLOOR TRUSSES

What follows is an explanation of what floor trusses are, the different types available, their advantages, and how to create and install a floor truss for your new home, building, or structure. Floor joists are horizontal parts of the flooring system that carry the weight of the home and support the structure. They can be made from wood, engineered wood, or steel, and each material has unique characteristics. Since joists are made to endure the load for an extended period, they must be durable.

Webs requiring CLRs will be denoted on the Truss Design Drawing with a rectangle with an “X” through it or a rectangle fully blackened on the web. CLRs attached to similar adjacent trusses are required to have a diagonal brace to transfer the forces from the CLR into a lateral force resisting system such as the roof or ceiling sheathing. Another alternative to field applied restraints are factory installed stacked webs and proprietary metal reinforcements that have been specially designed for this purpose. When oriented on the flat face of the board, webs will be cut with bevels on each end to create more surface area at the joint for a better fit. In some instances, square cut floor webs can be used but result in larger plates at the joint. Typical floor joists will not span the exact distances compared to floor trusses.

Floor trusses are often customized to the specific plans for a home, building, or structure. SBCA generates a large volume of timely, applicable information to its members and the industry at large on a wide variety of topics. This topical library pulls together the most relevant articles, news items, best practices and other online resources on each topic.

What Are Floor Joists, and What Are They Commonly Made of?

Anderson Truss Company Inc. floor trusses are widely known for reliable performance. We use strict guidelines to ensure a quality floor system with properly placed duct chases, bearing points, and special loads. Wooden floor trusses cost around $4 to 5 per square foot, whereas steel trusses for large projects cost $10 to $15 per square foot. A project must have heavy loads or spans for a floor truss to be included in the design.

Mattingly Lumber & Millwork relies on integrated software programs from MiTek - LBM Journal

Mattingly Lumber & Millwork relies on integrated software programs from MiTek.

Posted: Wed, 29 May 2019 07:00:00 GMT [source]

Trusses are made up of a series of panels, or the horizontal distance between the centerlines of two consecutive panel points along the top or bottom chord. Panels are imperative to the triangulation of the truss that allows the transfer of forces through the truss members and ultimately to the bearings. Typically, trusses are connected to the bearing temporarily with nails and permanently with a metal connector designed for uplift and lateral load considerations.

An automated roller is moved over the truss to press the barbs into the wood, which attaches to the connector plates. The ability to steal large lumber joists is also reduced, making them less likely to be stolen in great numbers. If you were to look at the truss from the side view, you would see a series of “N’s” in a row. The joints are fastened with connector plates made from barbed heavy steel gauges. Floor trusses can also be classified according to the materials used to make them.

We use joists to support floors and ceilings, while trusses can have various uses. Trusses are commonly more expensive than joists, but joists are easier to work with. Regarding weight distribution, trusses allow a more stable distribution, making them more popular than joists. Both options can be a good choice depending on the kind of project you need them for. Crafted by hand to your precise specifications, these strong and light trusses adapt to any structure. The SBCA Load Guide is designed to help users more easily understand, define and specify all the design loads applied to structural building components.

The carpenters will construct the floor trusses, so they leave the designated space between the top and bottom chords. While floor trusses are not always necessary, they can speed up installation time for plumbing, HVAC, and electrical systems. One of the considerations for building a house, storage, or other structure with flooring is whether to include floor trusses as part of the build. RedBuilt Open-Web Trusses offer a variety of solutions for a broad range of challenges. These strong, light and highly customizable Open-Web Trusses add design flexibility for owners/developers to create market-specific and relevant spaces.

In additional to the top and bottom chords, webs typically carry axial forces to the chords that eventually pass to the truss bearings. The vast majority of trusses utilize 2x4 dimensional lumber but webs can vary from 2x3 up to 2x12 lumber depending on the design. The grade and species of lumber used for webs is typically different from the chords of the truss to drive economic efficiency. Factors that impact the size of web members include on-center spacing, dead and live loads applied to the truss, span, and pitch, among others. The bottom chord is intersected by the top chord and web members at various points throughout the truss, creating a joint secured by metal connector plates.

Raised Floor Living, in conjunction with Southern Forest Products Association developed a table to help understand how trusses are built. Members that join the top and bottom chords to form the triangular patterns typical of trusses. See the resources below for more information on how to specify, install and brace floor trusses. After all the components have been put in place, the connector plates or steel gussets are placed on the joints.

No comments:

Post a Comment